POLYMERIC DISPERSANTS IN CROP PROTECTION FORMULATIONS

Abstract

Polymeric dispersing agents are widely used in plant protection products. This article provides brief information about the major types of polymeric dispersants.

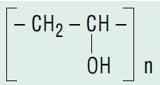

1. POLYVINYL ALCOHOLS

Standard not modified polyvinyl alcohol’s structure is as follows:

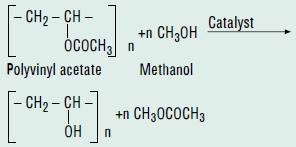

Polyvinyl alcohol polymers are based on the vinyl acetate monomer which is polymerized and then hydrolyzed. Examples of PVA products at the market are Kuraray Mowiol and Poval.

Mowiol and Poval

The different grades of Mowiol vary by the degree of polymerization of the polyvinyl acetate and its degree of hydrolysis (saponification). Wide range in terms of viscosities and hydrolysis degrees (3-85 to 28-99, or 40-88 and 56-98); fine particle sizes are also available for some grades to match specific application requirements.

All Poval types, for instance from 102 to 624, including the high molecular weight grade 235, show finer particles size distribution compared to equivalent Mowiol.

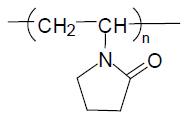

2. POLYVINYLPYROLLIDONE

Polyvinylpyrrolidone (PVP) is a linear nonionic polymer with the following structure:

- Polyvinylpyrrolidone homopolymer products vary by different molecular weight (Mw) in Daltons, e.g. Ashland products:

- Agrimer® 15: 8,000

- Agrimer® 30: 57,500

- Agrimer® 60: 406,000

- Agrimer® 90: 1,270,000

-

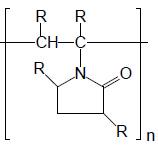

Alkylated Vinylpyrrolidone copolymers

The grafting of polyolefins onto PVP backbone gives products having widely diverse properties that vary with the molecular weight of the product, the length of the alkyl group, and the degree of alkylation of the polymer.

The examples of grafted PVP polymers are Agrimer AL series of Ashland in which products vary by VP/alkylation ratio:

- Agrimer AL 10: 90/10

- Agrimer AL 22: 20/80

- Agrimer AL 25: 50/50

- Agrimer AL 30: 30/70

- Agrimer AL 60: 20/80

-

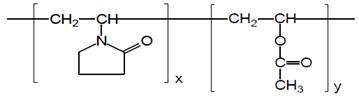

Vinyl acetate/vinylpyrollidone copolymers products are linear random copolymers of vinyl acetate and vinyl pyrrolidone:

Ashland series of the copolymers cover a range of PVP/VA ratios:

- Agrimer VA-3: 30/70

- Agrimer VA-5: 50/50

- Agrimer VA-6: 60/40

- Agrimer VA-7: 70/30

-

BASF series:

LUVITEC series – vinylpyrrolidone homo polymers vary by different molecular weights.

LUVITEC VA and COLLACRAL VAL are hydrophobic modified vinylpyrrolidone/vinyl acetate copolymers. By incorporating vinyl acetate (VA) comonomers into the VP polymer chain, specific properties of the VP homopolymers are modified.

3. COPOLYMERS POLYACRYLATE AND CARBOXYLATE

The examples of such copolymer dispersants are Agrilan series of AkzoNobel:

Agrilan 781 polyacrylate polymer, acid form

Agrilan 782 polyacrylate polymer, sodium salt

Agrilan 786 carboxylate polymer, sodium salt

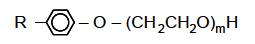

4. ALCOHOL ALKOXYLATES

The products of AkzoNobel are:

Berol series

Ethylan and Witconol series, e.g. Alcohol polyglycol ether : Ethylan NS 500 LQ

Example of Croda products are Atlas G series.

5. BLOCK POLYMERS

AkzoNobel: Berol, Ethylan, Monolan, Witconol

6. CASTOR OIL ETHOXYLATES

Examples are Berol series of AkzoNobel

7. NONYL PHENOL ETHOXYLATES

AkzoNobel: products from Berol series

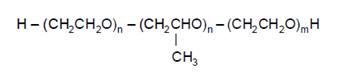

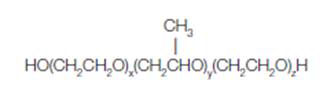

8. BLOCK COPLOLYMERS IN WHICH CENTRAL POLYPROPYLENE GLYCOL GROUP IS FLANKED BY TWO POLYETHYLENE GLYCOL GROUPS

BASF produces PLURONIC PE are nonionic surfactants and block copolymers. Pluronic PE product line of BASF varies by molar mass of polypropylene glycol block and percentage of polyethylene glycol in molecule.

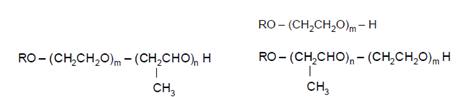

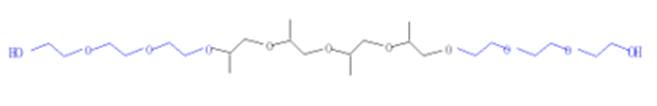

9. EO/PO BLOCK COPOLYMERS

EO/PO block copolymers are manufactured by reacting ethylene oxide and propylene oxide in combination with alcohol. EO/PO products have various applications as low-foaming non-ionic surfactants.

Examples of such products at the market are: Synperonic PE series of Croda

10. LIGNOSULPHONATES

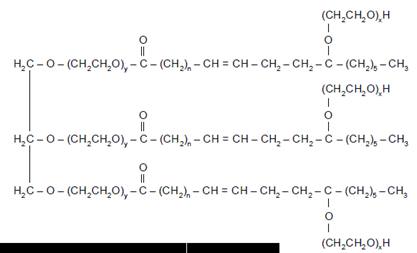

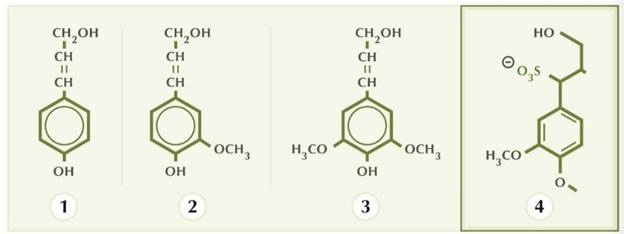

Lignosulfonates are a randomly branched, chemically multifunctional water-soluble biopolymers, produced as a value-added co-product of cellulose production. Lignosulphonates are derived from biomass, as a chemical derivative of lignin. The monomeric building blocks of lignin, as well as the sulfonated backbone of a generalized lignosulfonate structure, are depicted in figure below.

Monomeric building blocks of lignin: (1) p-coumaryl alcohol, (2) coniferyl alcohol, and (3) sinapyl alcohol. Structure (4) is a sulfonated monomeric building block of softwood lignosulfonate.

In crop protection formulations, lignosulfonates are used because of the ability of their molecules to adsorb at interfaces, thus providing dispersing, binding, complex-forming, and crystal growth-modifying properties required to stabilize the final product.

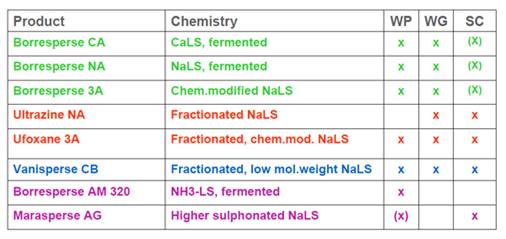

Examples of such products are Borregaard lignosulfonates:

The difference between these products is in their chemical structure, type of cation (Ca2+, Na+, NH4+), content of functional groups, degree of cross-linking and polymerization. Their purity is also a very important factor for their efficiency. The purity of lignosulfonates means minimum amounts and types of non-lignin components such as sugars, sugar acids, hydroxy acids and other organic acids, salts, and extractives.

Among Chinese manufacturers of lignosulfonates, the main are Shandong, Weifang, and Hubei plants.

Main Indian lignosulfonate manufacturer is Vertex Dye Chem.

The main Japanese lignosulfonate manufacturer is Nippon Paper Group.