Abstract

The use of nano-sized particles in pesticide formulations has gained significant attention due to their unique properties and potential benefits. However, the regulatory requirements surrounding nano pesticides pose challenges for their widespread adoption. This article explores the ability to achieve the advantages of nanotechnology in pest control through common conventional formulations.

Potential benefits of nano pesticides and regulatory concerns.

The past two decades have witnessed significant research efforts dedicated to exploring the potential of nano pesticides. Scientists have turned their attention to the development of nano formulations, which contain nano-sized particles acting as active ingredients, along with other nanomaterials possessing pesticidal properties.

These formulations could offer a range of potential benefits, including:

- Increased stiffness, permeability, thermal stability, solubility, crystallinity, and biodegradability.

- Enhanced systemic acquired resistance (SAR) against pests, enabling pesticides to penetrate plant tissues and exert systemic effects.

- Antimicrobial activity against various pathogens and their effectiveness in inhibiting weed growth.

By harnessing the power of nanotechnology, the development of eco-friendly and efficient solutions for crop protection could become a reality. However, there are also significant regulatory concerns that need to be addressed before nano pesticides can be widely adopted:

- It is not yet clear how nano pesticides will interact with the environment, and

- There is a serious concern that they will pose a risk to human health.

The regulation of nano pesticides is a dynamic process, with ongoing developments and no definitive consensus on their safety. In the European Union (EU), the regulation of nano pesticides is approached cautiously by the European Commission, and further research is expected to be conducted to assess the potential risks and benefits before any decisions regarding their use are made.

In the United States, there is no outright ban on nano pesticides, but certain restrictions are in place. The Environmental Protection Agency (EPA) has not yet established specific regulations for these products but is actively considering their development. Meanwhile, the EPA currently requires nano pesticide manufacturers to provide information on the potential risks and benefits associated with their products.

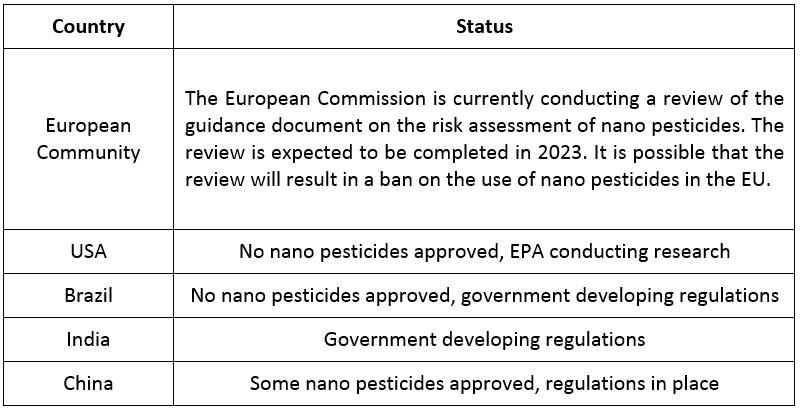

Similarly, Brazil, India, and China have not yet implemented specific regulations for nano pesticides. However, these countries have imposed certain limitations on their use and are actively engaged in researching the potential risks and benefits involved.

Overall, the regulation of nano pesticides remains in a state of flux, and their regulatory status can change over time. Until a clearer consensus is reached, further scientific investigation is necessary before widespread adoption of nano pesticides can occur.

Here is a table summarizing the regulatory status of nano pesticides in these countries:

Conventional formulations with potential of nano pesticides.

Despite the regulatory concerns surrounding nano pesticides, there have been long-standing conventional technologies capable of achieving nanoscale sizes of active ingredients, thus reaping the benefits associated with nanoparticles. These conventional pesticide formulations employ common techniques and approaches to attain the desired particle size without explicitly relying on nanotechnology. By thoroughly controlling the manufacturing processes, it becomes possible to reduce the particle size of A.I.s in the formulation or in the tank mix to the nanoscale, resulting in improved performance and efficacy.

It is important to emphasize that these conventional formulations, which incorporate nanoscale active ingredients, should not be classified as nano-pesticides. Consequently, they are not subject to the specific regulatory scrutiny faced by nano pesticides.

Before we delve deeper into the subject, let’s establish a clear definition of the particle size grades used in pesticide formulations, particularly in the context of nano formulations. To accomplish this, let's examine the different pesticide formulation grades based on particle size:

Nano formulation: This type of formulation consists of particles ranging from 1 to 100 nanometers in size, dispersed in a liquid medium.

Submicron formulation: This type of formulation encompasses particles measuring 100 to 1000 nanometers (0.1 to 1 micrometers) in size. Submicron particles exhibit some similar properties to nanoparticles but are not as small.

Micron formulation: This type of formulation comprises particles ranging from 1 to 10 micrometers in size (sometimes up to 20-30 micrometers). Micron particles represent the largest particle type utilized in pesticide formulations.

One common indicator of the presence of nano particles in a liquid formulation is its appearance, which can manifest as transparent or slightly opaque.

The size of particles in the formulation at which they will not scatter light and the system will appear transparent is typically around 100 nanometers (nm). This is because light waves are scattered by particles that are larger than about one-quarter of the wavelength of the light. The visible spectrum of light has wavelengths between 390 and 750 nm, so if the particle sizes in the formulation are below about 100 nm, the light can penetrate through the formulation without being scattered.

Now, let's explore the conventional formulation types that can be employed to achieve nano sizes of active ingredients.

ME (Microemulsions)

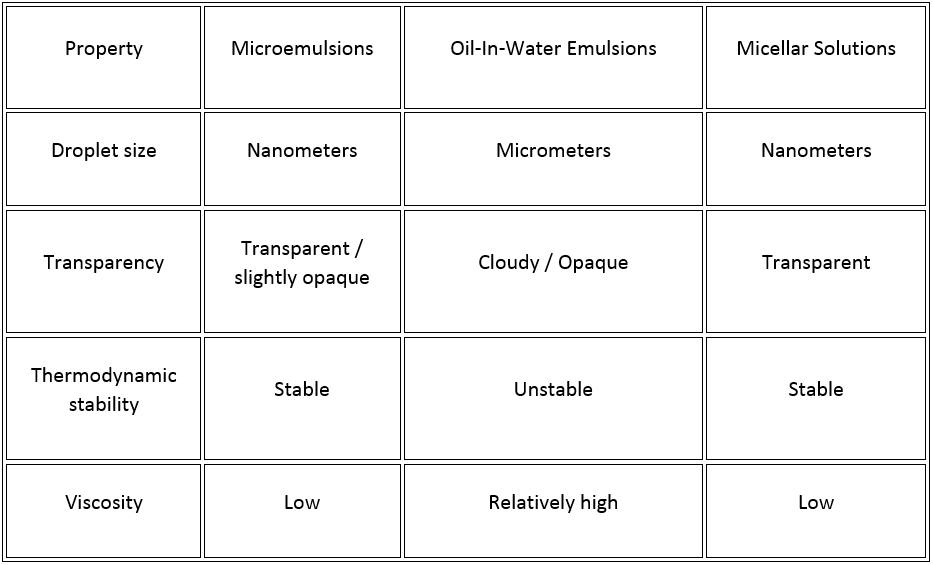

Microemulsions are a type of water-based emulsion (oil-in-water) that are characterized by their very small droplet sizes. This makes them transparent and thermodynamically stable, which are two important properties for pesticide formulations.

In a traditional oil-in-water emulsion, the oil phase is dispersed into water phase in the form of droplets. The size of these droplets is typically in the order of micrometers, which is large enough to be visible under a microscope. Microemulsions, on the other hand, have droplet sizes that are typically in the order of nanometers, which is too small to be seen under a microscope.

The small droplet size in microemulsions is achieved by using a combination of surfactants. When surfactants are added to a mixture of oil and water, they form micelles, which are small spherical structures with the hydrophilic parts facing the water and the hydrophobic parts facing the oil.

In a microemulsion, the micelles are so small that they are evenly dispersed throughout the solution. This gives the microemulsion a uniform appearance and makes it thermodynamically stable. Thermodynamic stability means that the microemulsion will not spontaneously separate into its oil and water phases.

In terms of whether microemulsions are more like real emulsions or micellar solutions, the answer is that they are both. Microemulsions are a type of emulsion, but they have the properties of micellar solutions as well. This is because the micelles in a microemulsion are so small that they behave like individual molecules. As a result, microemulsions have the properties of both emulsions and micellar solutions.

A micellar solution is a real physical solution consisting of micelles dispersed in a solvent. Micelles are self-assembled aggregates of surfactant molecules in water, where the hydrophilic head groups of the surfactant molecules face outward towards water, while the hydrophobic tail groups are oriented inward, forming a core.

While micellar solutions are real physical solutions, they are different from true solutions where solute molecules are dissolved on a molecular level. In micellar solutions, the solute (e.g., hydrophobic substances) is typically trapped or solubilized within the hydrophobic core of the micelles rather than being dissolved at a molecular level in the solvent.

In a microemulsion (ME) formulation containing pesticide active ingredients, the surfactant molecules form micelles, just as they do in a micellar solution. However, in a microemulsion, these micelles are dispersed throughout a continuous phase of water.

Microemulsions are thermodynamically stable systems consisting of small droplets of one immiscible phase (oil) dispersed within another phase (water), stabilized by surfactants. These systems can accommodate both hydrophobic and hydrophilic components, making them suitable for solubilizing and delivering a wide range of active ingredients.

A pesticide active ingredient is incorporated into a microemulsion can be present in several locations within the system:

- Micellar Core: The hydrophobic pesticide molecules can be solubilized within the hydrophobic core of the micelles formed by the surfactant molecules. The surfactant molecules arrange themselves with their hydrophobic tails facing inward, creating a favorable environment for solubilizing hydrophobic active ingredients.

- Interfacial Region: The pesticide molecules may also partition into the interfacial region surrounding the micelles. This region is the interface between the dispersed droplets (oil phase) and the continuous phase (water phase). The interfacial region can provide a surface for the interaction and partitioning of hydrophobic active ingredients.

In summary, micro-emulsion pesticide formulations and micellar solutions share similarities in surfactant behavior and solubilization capabilities. Both systems involve the formation of micelles, where surfactant molecules assemble to create a protective environment for the dispersed phase. Microemulsions have a dispersed system structure, combining properties of both emulsions and micellar solutions, making them suitable for pesticide formulation and delivery.

Here is a table comparing the physical properties of microemulsions, emulsions, and micellar solutions:

Preparing ME formulation

The key aspect of preparing a ME (microemulsion) formulation involves the solubilization of a water-soluble active ingredient in the aqueous phase which means the dispersion or dissolution of the hydrophobic molecules within the hydrophobic core of the micelles or in the interfacial region surrounding the micelles.

The mechanism of solubilization involves the following steps:

- Formation of micelles: The surfactant and co-surfactant molecules arrange themselves in a way that their hydrophobic tails face inward, creating a hydrophobic core. This core provides a favorable environment for the solubilization of hydrophobic active ingredients.

- Active Ingredient partitioning: The hydrophobic active ingredient molecules partition into the hydrophobic core of the micelles or into the interfacial region surrounding the micelles. The surfactant molecules surround and stabilize the active ingredient, preventing its aggregation and promoting its dispersion within the microemulsion.

- Solubilization capacity: The solubilization capacity of a microemulsion formulation is determined by the nature and concentration of the surfactants. The presence of a sufficient amount of surfactants allows for the incorporation of a higher concentration of hydrophobic active ingredient.

The selection of appropriate surfactants and optimization of their concentrations are crucial in achieving effective solubilization and stability of the active ingredient in the microemulsion.

ME formulations typically consist of particles with a mean diameter ranging from 10 to 50 nanometers. However, when diluted with water prior to field application, the formulation may lose its nano properties due to the reduction in the concentration of surfactant molecules and micelles. This can result in the disruption of the micellar structure and the dissociation of the micelles.

To maintain the stability of the micellar structure and preserve the nano size of the active ingredients in the ME formulation after dilution, it is crucial to ensure a sufficient concentration of suitable surfactants. This concentration should be significantly higher than the Critical Micelle Concentration (CMC). The CMC represents the concentration at which surfactant molecules spontaneously assemble into micelles, leading to changes in the solution's properties and behavior.

Above the CMC, the micelles continue to grow as the surfactant concentration increases. This concentration-dependent micelle formation plays a vital role in various properties of the solution, including solubilization capacity, reduction of surface tension, and emulsification ability. Therefore, maintaining a surfactant concentration well above the CMC is essential for preserving the stability of the micellar structure and ensuring the desired nano properties of the active ingredients in the ME formulation.

Another crucial factor for the stability of an ME formulation is the concentration of active ingredients (A.I.). It is important to note that the A.I. is typically incorporated within the micellar core of the formulation. Consequently, the concentration of the A.I. can be significantly lower compared to the concentration of the surfactants employed.

To achieve effective solubilization of the active ingredient and maintain stability, it is common to utilize lower concentrations of the active ingredient (A.I.), typically ranging from 0.1 g/L to approximately 10 g/L (equivalent to 0.01% to approximately 1%). This concentration range facilitates optimal solubilization while minimizing concerns such as phase separation or precipitation. Consequently, this type of formulation is particularly well-suited for active ingredients with high potency or activity.

DC (Dispersion Concentrates)

DC formulations can be another conventional alternative to nano pesticides. Dispersion concentrates (DCs) consist of an active ingredient dissolved in a water-miscible, polar solvent, combined with dispersants. The objective is to achieve stable and finely dispersed particles when diluted in water. The selection of suitable dispersing agents is crucial to ensure effective dilution properties in water.

Obtaining a fine particle size dispersion is of utmost importance. It is desirable for the dispersion to remain stable for a minimum of 24 hours after dilution. This stability is essential to prevent potential blockages in spray equipment and to maintain the bio-efficacy of the formulation.

There are a limited number of water-miscible or water-soluble aprotic solvents that are appropriate for use in DC formulations. A few examples of such solvents include Ethyl Acetate, Dimethyl Sulfoxide (DMSO), and N-Methyl-2-Pyrrolidone (NMP). It is important to note that only active ingredients (A.I.s) that are soluble in such solvents can be formulated as DC products, taking into consideration existing restrictions and limitations.

- Ethyl acetate is an exempt solvent under FIFRA, which means that it does not require a tolerance exemption for use in pesticide formulations. However, there are some restrictions on its use, such as it cannot be used in formulations that are intended for use on food crops.

- Dimethyl sulfoxide (DMSO) is an exempt solvent under FIFRA, which means that it does not require a tolerance exemption for use in pesticide formulations. However, there are some restrictions on its use, such as it also cannot be used in formulations that are intended for use on food crops.

- N-Methyl-2-pyrrolidone (NMP) is a restricted solvent under FIFRA, which means that it requires a tolerance exemption for use in pesticide formulations. NMP is a known neurotoxin, so it is also only allowed for use in formulations that are applied to non-food crops.

The particle sizes of solid A.I. precipitated from DC formulations, after dilution in water, can vary depending on the composition of the formulation and the active ingredient. Commonly, DC formulations yield particle sizes of A.I.s in the sub-micron range, typically ranging from 100 nanometers to 1 micrometer. If the solid particles of the DC formulation, once dispersed in water, fall within the nanoscale range, the resulting dispersion in the tank mix can be regarded as a nano pesticide. In such instances, the nanoparticles contribute to the properties of the active ingredient, offering potential benefits associated with nanotechnology, such as increased surface area, enhanced bioavailability, and improved efficacy.

It is important to acknowledge that achieving and maintaining stable and uniform dispersions in the nanoscale range can present challenges, including particle aggregation, sedimentation, and stability concerns. These considerations highlight the significance of careful formulation and thorough testing when dealing with nanoscale DC formulations.

The selection of the appropriate dispersants in optimal ratio and concentrations is crucial in achieving the stable nano-sized dispersion of A.I. particles precipitated from DC formulation after dilution.

Another key factor in achieving nano-sized particles through the dilution of DC formulations lies in the final concentration of solid A.I. in water, which should be very low. Let's take, as an example, the fungicide formulation Heritage Maxx of Syngenta, which contains 95 g/l of Azoxystrobin in DC form. According to the published product’s MSDS, Azoxystrobin in this formulation is dissolved in Tetra-Hydro Furfuryl-methanol which is unlimitedly soluble in water.

The recommended application rate for Heritage Maxx is 2.5 l/Ha, with a typical water volume of 200-400 l/Ha for optimal results. Let’s calculate the concentration of Azoxystrobin in the spraying water:

95 g x 2.5 l = 237.5 g/Ha

237.5 g: 200 l of water gives ~1.2 g/l or 0.12%, for 400 l/Ha of water, the concentration is 0.06%

Therefore, the final concentration of solid Azoxystrobin particles, after dilution in the spraying water, ranges from 0.06% to 0.12%.

Such low concentrations of solid particles, achieved through the dispersion of the DC formulation in water, allow for the formation of pesticide particles in the nano size range.

Conclusion

The article highlights the possibility of obtaining nano-sized droplets/micelles of A.I.s when using conventional formulation techniques for ME or solid particles of A.I. in the case of DC, diluted in spraying water. This approach allows us to take advantage of the benefits of nano pesticides without having to adhere to nano pesticide regulations. Although implementing this method poses certain challenges, it is already being practiced in the worldwide pesticide market. Thus, by leveraging conventional approaches, we can unlock the potential benefits of nanotechnology in pest control.