Abstract

Aerial drone spraying has emerged as a cutting-edge and highly effective technique for pest control, providing accurate targeting, accessibility to hard-to-reach areas, and reduced human exposure to chemicals. The author explores the key factors that make ULV formulations suitable for aerial drone spraying and shares his expertise in selecting Low VOC solvents, which is crucial for successful UAV application, contact the author.

What is aerial drone spraying of PPP?

Drone-based pesticide spraying is a mostly innovative and efficient approach to pest management with strong advantages over traditional methods: precise targeting and application, access to difficult-to-reach areas, and minimization of human exposure to chemicals.

Despite having smaller tank capacities ranging only tens of liters, UAVs (Unmanned Aerial Vehicle) for PPP application provide distinct advantages over planes. Drones can spray with precision and flexibility, flying at low altitudes of 2 to 5 meters. They can maintain a buffer anti-drift separation zone (swath) of 2.5 to 7 meters and apply a Volume Application Rate (VAR) of less than 5 liters per hectare (L/ha). These capabilities make drones an excellent choice for aerial applications in agriculture and pest control.

The UAVs are equipped with a special Spraying System (tanks, pumps, and nozzles), Flow Control Mechanisms, GPS for precise flight paths, Payload Release Mechanism, Sensors and Data Collection, and a Flight Control System with onboard computers and software. Specialized anti-drift nozzles generate a wider droplet size distribution including larger droplets and applying high-concentrated pesticide formulation at low pressure for improved coverage and reduced drift risk.

During aerial application, the emulsion droplets of EC ULV formulations undergo atomization, forming a fine mist with droplets of oil, water, and emulsion. Each emulsion droplet consists of a water droplet encapsulating multiple smaller oil droplets. This enhances the dispersion and coverage of the formulation over the target area.

For drone spraying of ULV formulations, an optimal droplet size with a Volume Median Diameter (VMD) ranging from 10-100 microns to 100-230 microns, falls within the “Extremely Fine” (<60 microns) to “Fine” (106-235 microns) groups according to ASABE classification (American Society of Agricultural and Biological Engineers). Commonly, the droplet size distribution is characterized by DV0.1 at about 100-125 microns, DV0.5 at approximately 250 microns, and droplets smaller than 100 microns accounting for about 5% of the distribution.

ULV EC formulations.

ULV (Ultra-Low-Volume) refers to a method of pesticide application that involves using extremely low volumes of liquid formulation to cover a large area. As such, it is an ideal pesticide formulation suitable for spraying using plant protection UAVs at low volume. A major difference between ULV and conventional applications is that the ULV method requires little or no diluent, whereas conventional methods require large quantities of diluents such as water or compatible oils. ULV sprays are an oily pesticide formulation (EC) made by dissolving the active ingredient into a solvent with a high boiling point, added with adjuvants. ULV formulations are designed to produce fine droplets which allow for efficient dispersion and uniform coverage of the target area.

What makes ULV formulation suitable for application by UAV? What are the keys to success?

Besides implementing special measures and equipment during application, specific criteria must be fulfilled regarding the physicochemical properties and composition of ULV formulations:

- The formulation should be designed to be compatible with the drone's spraying system, ensuring smooth operation without causing damage or clogging. This requires formulation stability, suitable viscosity, surface tension and compatibility with adjuvants applied with the formulation.

- Due to the extremely low volume of the formulation being applied per hectare of the crop, a high concentration of the active ingredient is necessary to ensure sufficient efficacy.

- It is crucial to have an essentially non-volatile formulation. Droplets from volatile formulations tend to shrink at variable rates due to evaporation, which is influenced by environmental factors such as temperature, relative humidity, and flowing distance. Conversely, less volatile droplets are more likely to retain their initial size, resulting in a more consistent and desirable droplet size distribution in the sprayed mist. Slowing down the evaporation of the active ingredient after application also allows it to remain on the target surface for a longer period. This extended contact time can enhance the effectiveness of the pesticide by prolonging its interaction with pests or target plants.

Let's take now a closer look at how these requirements are met in ULV formulations designed for aerial drone spraying.

Viscosity.

The common viscosity of emulsion in the spraying mist is about 1–1.5 cPs, while the viscosity of the formulation itself can vary from 20 to 100 cPs. By formulating pesticides within this viscosity range, the formulations can be effectively atomized and distributed by application equipment.

Surface tension.

The common surface tension of the emulsion in the spraying mist is about

40 mN*m-1.

Adjuvants.

When preparing a tank mix of a ULV formulation for aerial application, it is common practice to add certain adjuvants to the tank mix in addition to the formulation itself. Adjuvants are commonly added to the water in the spray tank before the ULV formulation is introduced. Adjuvants can improve the spreading, sticking, wetting, or absorption properties of the formulation leading to better efficacy and coverage. Types of adjuvants used: nonionic surfactants to reduce surface tension and improve wetting and spreading on leaf surfaces; drift control agents to minimize off-target drift by modifying droplet size or improving droplet deposition; penetration enhancers to facilitate the entry of the active ingredient into the plant tissues; stickers to promote adhesion of the formulation to the plant surface, reducing runoff. Examples of the adjuvants include alkyl polyglucosides, ethoxylated fatty alcohols, ethoxylated vegetable oils, silicone-based adjuvants, etc.

Lower evaporation possibility. In ULV formulations for aerial application, the oil carrier plays a crucial role in facilitating the dispersion and application of the active ingredient. Low VOC (Low concentration of Volatile Organic Compound) carrier (solvent) is the key factor that makes ULV formulation suitable for aerial drone application.

Low VOC formulations have been developed to reduce the emission of volatile compounds during pesticide application. These formulations are designed to have lower vapor pressures and reduced volatility compared to traditional formulations. In addition to better control of droplet size distribution in the sprayed mist, this reduces the potential for air pollution and decreases the environmental impact associated with pesticide application. Using low VOC formulations, the exposure of both pesticide applicators and individuals in the vicinity of the application area to volatile compounds is reduced. This can help mitigate potential health risks associated with VOC exposure.

Regulatory Compliance: Many regions and regulatory bodies have established restrictions or guidelines on VOC emissions. Using low VOC formulations ensures compliance with these regulations and demonstrates a commitment to environmental stewardship. The VOC content of a ULV formulation is determined by the oil carrier (solvent) used in the formulation.

So, which solvents have Low VOC levels, and what is considered to be a Low VOC level?

Different countries or regions may have their own regulations or guidelines that define what qualifies as a "low VOC" solvent and set specific VOC content limits. Here are some common definitions of low VOC levels: 0-150 g/L: this is the definition of low VOC levels used by the California Air Resources Board (CARB). 0-50 g/L: this is the definition of low VOC levels used by the U.S. Environmental Protection Agency (EPA). It is important to note that these are just general definitions, and the specific definition of Low VOC levels may vary depending on the product and the regulatory agency.

Total VOCs are defined as any chemical compound based on carbon chains or rings with a vapor pressure greater than 0.01 kPa (~0.075 mmHg) at 20°C.

To ensure compliance of the VOC content of Low VOC solvents, it is recommended to consult regulatory authorities, industry associations, or solvent suppliers who can provide the most up-to-date and region-specific information.

Manufacturers and suppliers of Low VOC solvents may provide information on the VOC content of their products through safety data sheets (SDS) or technical specifications. These documents can help determine the specific VOC content values for the Low VOC solvents they offer.

One of the commonly used methods for VOC determination is TGA. TGA VOC by LOD (Loss on Drying) is a method used to determine the volatile organic compounds (VOCs) content in a sample by measuring the weight loss during a controlled heating process.

TGA stands for Thermogravimetric Analysis, which is a technique that measures weight changes of a sample as a function of temperature.

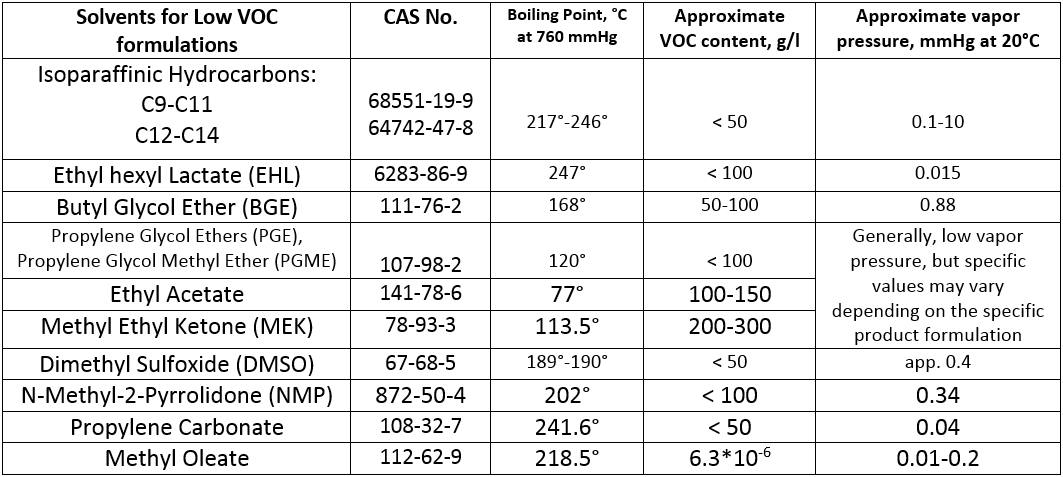

In the table below you can find some approximate data for VOC of different solvents. However, it is important to note that the specific values may vary depending on the specific product (solvent) formulation from different manufacturers and applied testing methods.

Approximate VOC levels in some of Low VOC solvents

CONCLUSION

ULV formulations are a promising option for aerial drone application. The precise targeting, improved coverage, and reduced environmental impact offered by drones make them an ideal choice for effective pest control. However, the use of Low VOC solvents is essential to ensure the success of ULV formulations for UAV spraying techniques.

Low VOC solvents are important for several reasons. First, they help to better control the droplet size distribution in the sprayed mist. This is important for ensuring that the pesticide is applied evenly and effectively. Second, low VOC solvents comply with regulations in many countries and regions. Third, they minimize air pollution and mitigate health risks associated with volatile compounds.

For these reasons, it is crucial to select appropriate low VOC solvents when developing ULV formulations for UAV applications. The selection of the right solvent will depend on several factors, including the type of pesticide being applied, the environmental conditions, and the local regulatory requirements. However, by selecting the right solvent, you can ensure that your formulations are effective, compliant with regulations, and environmentally friendly.